To operate in real-time, complex simulation models such the ones implemented in STREAM-0D need to cut down computational times while saving the reliability of information. This is where the notion of ‘sparsity’ comes into play.

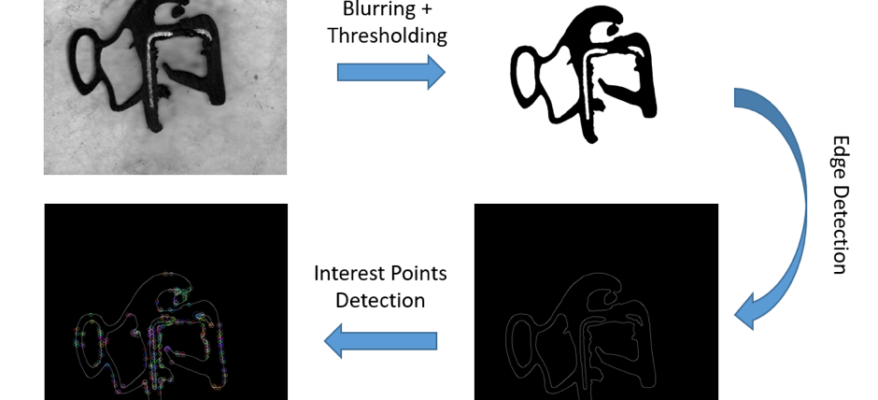

Extracting critical dimensional information from images for cross sections of extruded rubber seals

Standard Profil makes sealing profiles for automotive manufacturers all around the world and it is one of STREAM-0D end-users. In this article Cetri, that in the project leads data fusion, data sparsification and data-driven modelling, provides a glimpse of the activities carried out on Standard Profil’s production line.

On the road to create the factory of the future

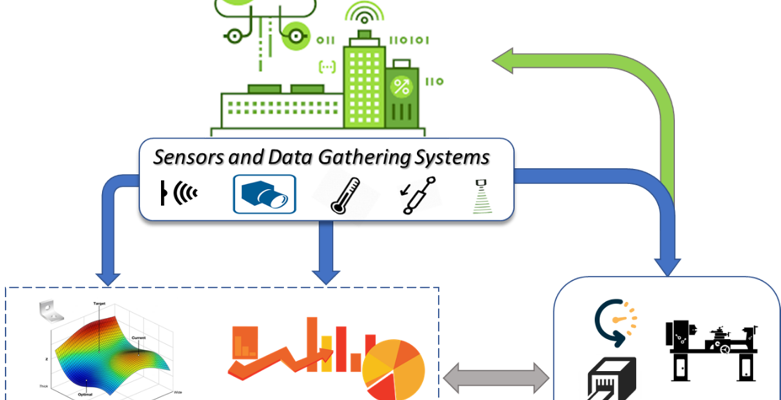

The idea of ‘Factory of the future’ is strongly connected with transformation. Factories transform production processes introducing intelligent sensors, gathering systems and triggers the need for more accurate data. Zero-Defect Manufacturing (ZDM) paradigm lays within the very concept of factory of the future.

STREAM-0D: prediction and self-adaptation in the extrusion process

The extrusion of profiles is, for many reasons, a complex process: overcoming this complexity would result in a remarkable advancement in the manufacturing process. STREAM-0D project is tackling this challenge by implementing technologies able to monitor and control different aspects of the process. Standard Profil, one of STREAM-0D end-users, provides an insight on this subject.