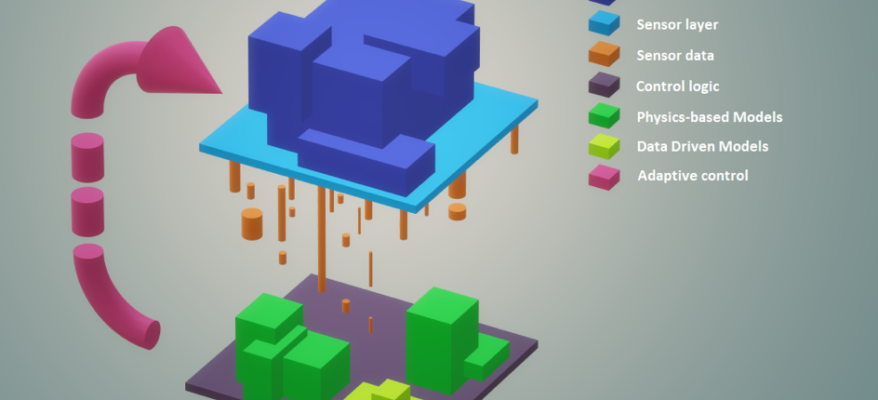

In an interconnected, smart factory the physical and the virtual space run in parallel to maximize process efficiency. STREAM-0D project is leading the way towards the next industrial revolution, thanks to the development and combined implementation of innovative technologies such as ROMs (Reduced Order Models).

Big Data analytics reduce process flaws and save manufacturers’ time and money

Smart Manufacturing which is often equated with ‘Industry 4.0’ leverages the Big Data trend of advances in volume, velocity, and variety of data, and applies ‘Big Data analytics’ to make sense of it by improving existing analysis capabilities and providing new capabilities such as predictive analytics.

Data management turns data into information

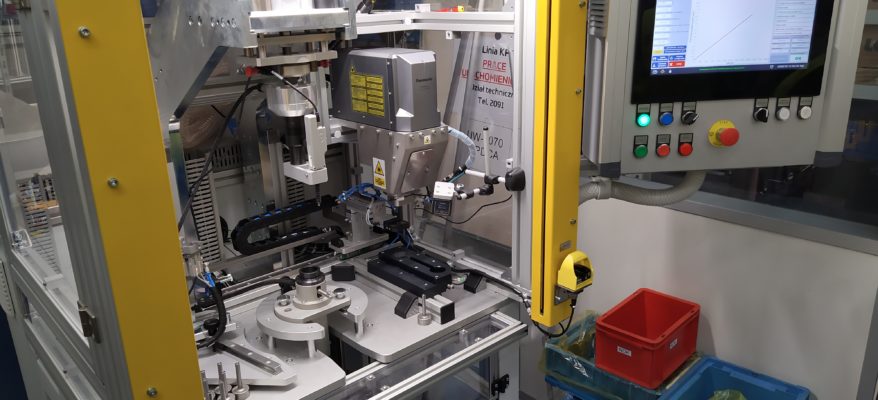

Thanks to the implementation of the STREAM-0D solution, Standard Profil experienced great improvements in data management: process data are now merged with product data, allowing a better control of the production. It is Standard Profil itself that, in this article, tells the story of this advancement.