On the road to create the factory of the future

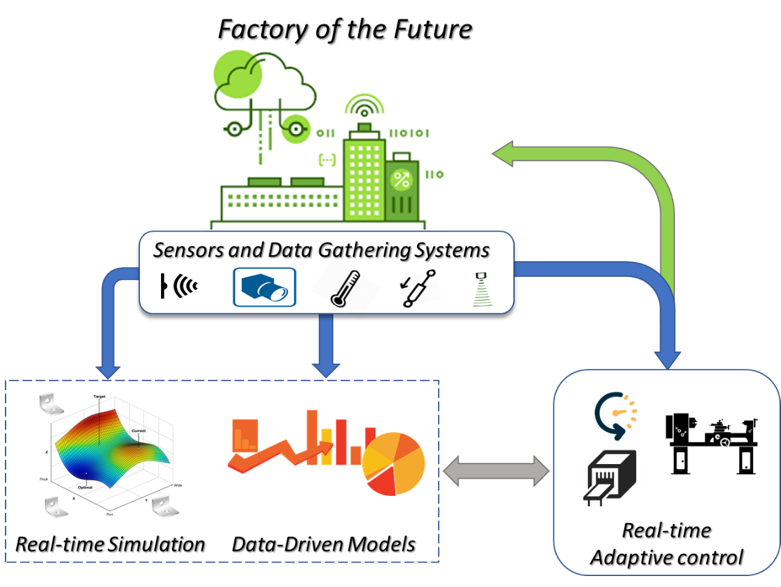

The idea of ‘Factory of the future’ is strongly connected with transformation. Factories transform production processes introducing intelligent sensors, gathering systems and triggers the need for more accurate data. Zero-Defect Manufacturing (ZDM) paradigm lays within the very concept of factory of the future.

The pillars of a so-called factory of the future include methods and techniques such as real-time modeling and simulation, data processing and data analytics techniques, adaptive control methods and, most importantly, innovative and accurate monitoring and inspection systems.

It is evident that the concept of factory of the future requires a network of connected devices and machines, sensor equipment and inter-connected systems. On the one hand, a constant stream of data is required to monitor the line and, on the other, tracking systems are needed to perform a continuous tracking of the manufactured product – control that also includes the compliance with certain features of the said product.

All about accuracy

However, a great challenge coming with this transformation of the industry, is related to the need for accurate data and, even more, for data describing in detail the physical characteristics of the product. To get these data, highly innovative measurement systems as well as systems able to be implemented in a real production line are needed; these, have to be also accurate, reliable, robust and as less intrusive to the line as possible.

Advancements in electronics, optoelectronics and in general in sectors related to sensors development, made this need feasible to a large extend. Moreover, the gathered data can automatically be stored in the cloud making their processing even easier. Overall, the factory of the future is based on intelligent sensors and data gathering systems. The whole production line is interconnected, generating data necessary for providing at any time the status of the line.

The activities of STREAM-0D project include the integration and development of innovative sensors and inspection tools at a process level in order to feed simulation models and data driven models with real data from the line at any given time; this, to allow the prediction of the produced part.

This real-time data gathering represents the basic pillar to apply a truly successful adaptive process control and, eventually, to reach a Zero-Defect Manufacturing (ZDM) process.

—

This article was provided by Demetris Petrides, Alexios Papapacharalampopoulos and Panagiotis Stavropoulos of the Laboratory for Manufacturing Systems and Automation (LMS) – Department of Mechanical Engineering and Aeronautics (University of Patras, Greece)

Follow STREAM-0D on: