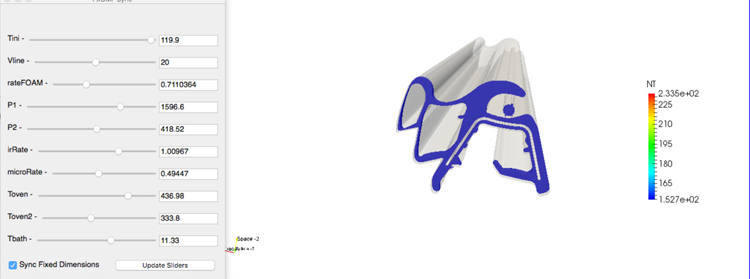

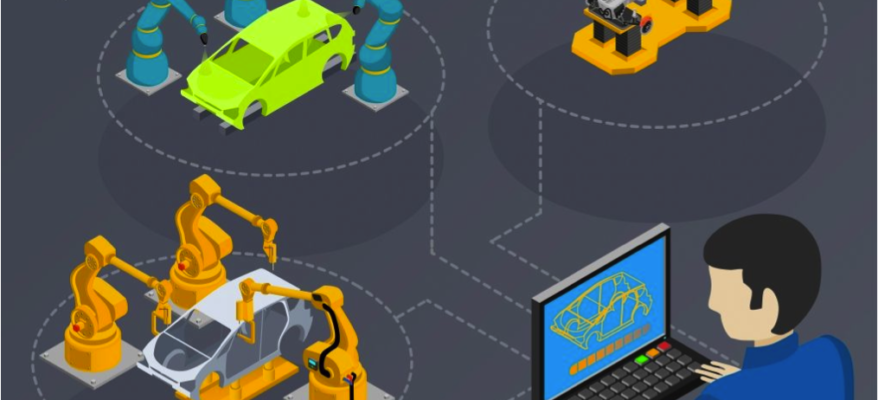

In an interconnected, smart factory the physical and the virtual space run in parallel to maximize process efficiency. STREAM-0D project is leading the way towards the next industrial revolution, thanks to the development and combined implementation of innovative technologies such as ROMs (Reduced Order Models).

Discrete manufacturing: model-based process optimization and control

The ways in which process manufacturing and discrete manufacturing are respectively controlled differ a lot. Dealing with discrete manufacturing, STREAM-0D requires the implementation of sophisticated analysis within the process. This activity is managed by STAM, which in this article for the Bits Of STREAM-0D inititative, outlines the features of such approach. STAM is an Italian …